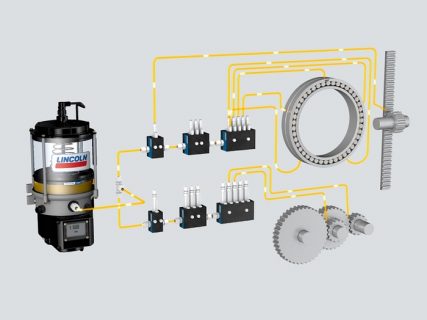

SKF announced the introduction of its Lincoln SLC metering device for grease. Developed for use in single-line lubrication systems, this compact metering device features a compact and modular design for less jointing and decreased risk of leaking.

High venting capability

Featuring a spring-reset control piston, the metering device has a high venting capability for compatibility with greases up to NLGI 2. The device provides reliable operation in harsh conditions and low temperatures. Delivery volume can be either adjusted via regulating screws or set with dosing screws, both options ensure each lubrication point receives the required amount of lubricant.

The SLC is available in two versions – the SLC1 for one to 12 outlets and the SLC2 for one to six outlets. Both are offered with BSP or NPT threads and in C3 corrosion classification. Metric and imperial sizes are included for inlet and outlet fittings.

With the most compact construction in its class, the SLC is suitable for use in renewable energy, construction and mining applications, as well as when replacing smaller, mid-pressure, dual-line lubrication systems.

Combining more than 100 years of SKF and Lincoln expertise, SKF offers the industry’s most complete portfolio of innovative lubrication solutions – from manual lubricators and tools, to the most advanced centralized and automatic lubrication systems.

Leave a Reply