Rehabilitation & expansion to 200,000m3/d

WABAG was awarded the contract for the Design and Build Project of Upper Ruvu WTP by Dar Es Salaam Water & Sewerage Authority (DAWASA) for a value of US$ 40m.

The works included the rehabilitation and expansion of the intake and raw water transmission system at Ruvu River and the building of a new water treatment stream with an output of 130,000m3/d as well as pumping of the combined outputs from the WTP to the service reservoirs at Kibamba and Kimara.

The expanded WTP produces 200,000m3/d safe drinking water daily for over 700,000 people. Commissioning was completed in July 2016.

Main components of the Upper Ruvu Water Supply System:

- River water intake: Located 65 km west of Dar es Salaam on the banks of The Ruvu River: Screens, pre- lift pumps, grit channels and raw water pumps located.

- Raw water transmission: A combination of 2 mains conveying raw water to a distance of 6.3 km, from the intake to the Upper Ruvu WTP (URWTP.

- Upper Ruvu WTP:

– Situated 6 km away at Mlandizi

– Comprising of 3 treatment streams: chemical conditioning, clarification, filtration and disinfection, treated water storage and pumping station, as well as associated bulk electrical supplies.

- Treated water transmission mains:

3 transmission mains of diameters ranging from 600 to 1200 mm conveying treated water to a distance of about 51 km from the UR plant to Kimara Reservoir.

Features

- Rehabilitation of existing equipment of raw water intake, transmission and WTP with a capacity of 82,000m3/d

- Design and Build of a new water treatment line with a capacity of 130,000m3/d

- Treating Upper Ruvu river water for drinking water production for about 700,000 people in Dar es Salaam

Scope of work:

- Rehabilitation and expansion of raw water intake and transmission system.

- Building of a new water treatment stream with an output of 130,000 m3/d

- Treated water pumping of combined outputs to the service reservoirs at Kibamba and Kimara.

Scope of work Water Treatment Line:

- Flow division/Mixing/Coagulation /Flocculation chamber and associated mixers, flocculators, chemical injection points

- 130 MLD design output sludge blanket clarifiers.

- 130 MLD design output rapid gravity filters

- Chemical storage solution, mixing and dosing equipment

- Gaseous chlorination (1 tonner drums)

- Building for office and administration, chemical plant, filter gallery, backwash pumps, service water pumps, chlorination

- Sludge thickening plant

- Associated electrical works

- Internal and external pipe works

- Access roads and drainage

- Miscellaneous works including demolition and replacement of existing staff housing units, security fencing.

- Bulk Electrical works including:

– 33/3.3 kV 12MVA transformers (2nos),

– 3.3/0.4 kV 0.5MVA transformers (2nos)

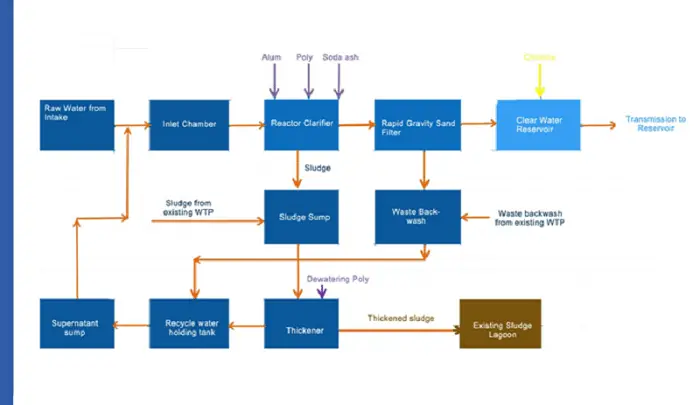

Process flow diagram:

Client

Dar es Salaam Water & Sewerage Authority (DAWASA)

Award of contract

2014

Financing

Funded by EXIM Bank of India under Indian credit line

Start of construction

2015

Commissioning

2016

Raw Water

River water

Product

Drinking Water

Main parameter

Turbidity removal, Disinfection

Technology

Multi-stage-process

Capacity

Extension from

82,000 to 200,000m3/d

Contacts;

VA TECH WABAG LTD.

WABAG HOUSE“

No. 17, 200 Feet Thoraipakkam – Pallavaram Main Road,

Sunnambu Kolathur, Chennai 600 117, India

Tel.: +91-44-3923 23 23

E-Mail: [email protected]