Mobile and locomotive cranes are a vital piece of equipment, standard on many construction sites and industrial zones. It is no surprise that these massive pieces of equipment can cause major damage if they are not used correctly, which is why crane inspection services are essential to promoting workplace safety.

According to the latest data from the US Bureau of Labor Statistics, there are 44 fatalities involving cranes every year, along with hundreds of injuries. The majority of these injuries are caused by contact with an object or equipment, a fall, transportation incident, or contact with electrical currents.

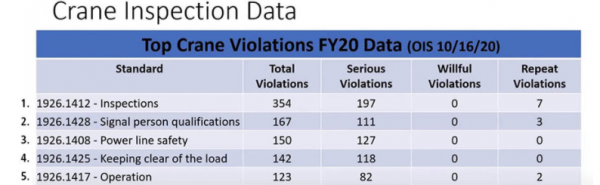

Additionally, many construction companies fail to maintain the necessary safety standards for crane and rigging equipment. Every year, OSHA issues hundreds of violations and fines due to serious safety infringements, including failing inspections.

The best way to improve crane safety in the workplace may be to use a crane inspection service to locate any safety hazards or violations. Here’s what you need to know about hiring this kind of inspection service and why it may be the best choice for your job site.

1. Who is Certified to Inspect a Crane?

OSHA states that only qualified personnel can conduct a tower crane inspection or mobile crane inspection. In OSHA Standard 1926.1401 Subpart CC, OSHA states that a competent person must perform all inspections. Per OSHA, a competent person means “one who is capable of identifying existing and predictable hazards in the surroundings or working conditions which are unsanitary, hazardous, or dangerous to employees, and who has authorization to take prompt corrective measures to eliminate them.”

The competent person responsible for the crane inspection must have specialized knowledge. First, they need to know all of the OSHA safety requirements for the equipment, such as lockout/tag out systems and load charts. Second, they must be familiar with the machine itself to identify any mechanical issues.

For this reason, it is highly recommended to use a crane inspection service to thoroughly check all aspects of your rigging equipment. Although a crane operator may be experienced and seemingly “qualified”, they may not know the latest OSHA regulations or catch every issue.

Instead, it is best to hire inspectors or a crane and rigging consultant with a certification from organizations such as NCCCO (National Commission for the Certification of Crane Operators).

2. When are Inspections Needed?

According to OSHA’s 1926.1400, any power-operated equipment including tower, mobile, and locomotive cranes must meet set safety standards. Additionally, the American Society of Mechanical Engineers (ASME) also has a code of standards for the inspection process of cranes as stated in ASME B30.3 and B30.5.

In order to meet these set standards, a tower crane inspection or mobile crane inspection must be completed before each shift. The inspector should look over the crane for any signs of safety issues or hazards, such as damage to the equipment or parts which are not secured correctly.

Tower lifting and rigging equipment such as hooks, slings, and cables must be inspected every month to detect signs of wear or damage. Larger pieces of equipment, such as locking devices and braking systems, must be inspected every 3 to 6 months.

There are also special situations that require inspection. For instance, a modified equipment inspection is required if any parts have recently been replaced or altered. Post-assembly inspections must be done after a crane has been transported to a new job site.

Finally, a comprehensive annual inspection is required for all equipment by a qualified person or agency, such as a crane inspection service. This will be a more thorough inspection of all parts and pieces of the crane and equipment to note any damage, safety hazards, or OSHA violations.

3. What Documentation Does OSHA Require?

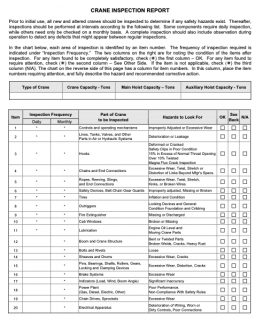

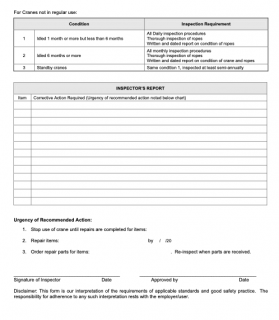

All inspections (including daily ones) must be documented and kept on record. OSHA provides pre-made crane inspection report checklists that organize all of the needed information. During daily and monthly inspections, the date, inspector name, the serial number of the hoist, and any noted damage must be listed.

Annual crane inspections go far more in-depth and require detailed information on specific parts. An annual tower crane inspection or mobile crane inspection would include:

- Checking for cracked, rusted, or deformed hardware

- Loose bolts

- Worn or cracked sheaves and drums

- Damaged or worn pins, bearings, shafts, gears, rollers, and locking devices

- Signs of wear on braking systems parts, including the linings, pawls, and ratchets

- Significant inaccuracies in load or wind indicators

- Excessive chain or wire rope stretch

- Electrical control issues

The inspector must take careful notes and document any discrepancies or concerns.

Conclusion

Tower crane inspections are required by law to ensure a safe working environment that is free from safety hazards. Therefore, all inspections must be conducted carefully and correctly each time.

The only people who can conduct adequate inspections are those who have received special training for that specific equipment. The best way to ensure that your cranes pass inspections is to partner with a qualified crane inspection service.

Author Name: Craig Hautamaki

Author Bio: Craig Hautmaki works with Colorado Crane Operator School, an industry leading crane and rigging training school and safety consulting company. He is an NCCCO accredited practical examiner and has over 15 years of experience in Oil and Gas, Construction, and General Industry.