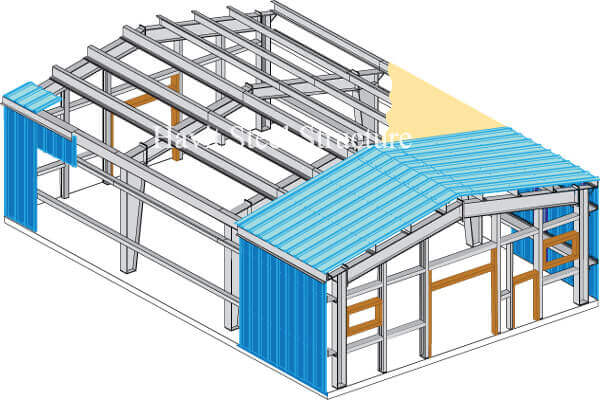

A prefabricated steel structure for warehouse buildings is usually composed of steel beams, steel columns, steel truss, and other components made of section steel and steel plates. Each part connected by welds, bolts, or rivets. But why even choose prefabricated steel structure warehousing as an option?

The primary function of the steel warehouse building is to store goods, so ample space is one of the characteristics of the warehouse. The steel structure warehouse combines this feature. The warehouse with a steel structure has a large span and a larger utilization area.

Steel structure buildings are light in weight and lighter than other types of buildings with the same strength. Besides, large-scale warehouses need large spans, and steel structures are most suitable for large-span buildings, such as factories, stadiums, and so on.

And also, the warehouse building needs are more urgent.

Time is the most significant advantage of the steel structure warehouse building. The construction period is shorter, the construction is more convenient, and the time and investment costs significantly reduced. Besides, with the development of the business or other factors, some steel structure warehouses will face the problem of relocating addresses.

Another advantage of the steel structure highlighted is that due to its lightweight, a relocation project will be more convenient and environmentally friendly and recyclable. In an era of severe air pollution, once the steel structure warehouse is no longer required, it can still be recycled without pollution.

Design of a steel structure warehouse

Focus on the load-bearing design

The design of the steel structure warehouse needs to consider the load-bearing design taht will allow it to withstand rainwater, snow pressure, construction load, and maintenance load. And also, the design has to fulfil functional load-bearing capacity, material strength, thickness, and force transmission method requirements, load-bearing ability, cross-sectional characteristics of the version, etc.

The load-bearing problems of the steel structure warehouse design need to be well-considered to reduce the warehouse’s damage capacity. It is also a construction method for the daily maintenance of steel structure and extended service life.

Pay attention to lighting design

A good lighting effect is conducive to energy saving. Otherwise, indoor lighting is needed all day and night, which will undoubtedly an increase in energy consumption. There will be the need to design and arrange lighting panels at specific locations on the metal roof or installing lighting glass, using natural light where possible, and doing waterproof work at the same time to maximize the service life.

Metal warehouse vs traditional concrete warehouse?

As a primary storage facility, warehouses are classified according to the role of the warehouse in the commodity circulation process or the characteristics of goods. To cope with the different demands placed on warehouse construction in the market, in recent years, more and more steel structure warehouse buildings are coming up, an indication that many entrepreneurs are abandoning the concrete structure construction model that has been used for many years.

The construction of the steel structure warehouse is rapid, and the response to sudden needs are apparent, which can meet the sudden storage needs of the enterprise.

The steel structure warehouse is a dry construction, which has outstanding environmental protection advantages. It can reduce the impact of project construction on the environment and nearby residents, which is better than the wet construction of reinforced concrete buildings.

Steel structure warehouses can save construction costs and workers’ costs, compared with traditional concrete warehouses. The cost of building a steel structure warehouse is 20% to 30% lower than a typical warehouse construction cost, and it is more secure and stable.

The steel structure is light in weight, and the building materials used in the walls and roof are much lighter than those in brick-concrete walls and terracotta roofs, which can effectively reduce the overall weight of the steel structure warehouse without compromising its structural stability. At the same time, it can also reduce the transportation cost of components formed by off-site migration.

Metal warehouse vs wooden construction?

Cost-effectiveness

Steel construction is more affordable than wooden construction.

Faster design and construction process.

If your warehouse plan submitted to a steel structure manufacturer company, the building will be pre-designed and manufactured by experts. It makes the entire process from start to finish more economical, resulting in ready-made steel construction components that are shipped directly to the worksite.

It has reduced labor costs

Since the warehouse is mostly prefabricated, construction time can reduce by as much as 30% to 50% or more based on the experience level of the construction personnel. Time is money, so the faster you can build, the less money you spend on labor.

Reduce maintenance costs

Due to the low maintenance cost of the steel structure, the building owner saves general maintenance, repair, and replacement during the entire life of the building.

Endurance

Steel structures can resist many common threats to wood, such as decay, mildew, pests, and fire. Moreover, the carefully designed steel structure is more resistant to wind, snow, and seismic activity. It is why steel structures can often be buildings that will not fall after a typhoon. Usually, when the community needs a disaster evacuation center, the city will turn to steel-framed gymnasiums, schools, and other municipal buildings, which they know are the most reliable and most resilient in the area.

Clearspan

The fewer structural obstacles the building requires, the more work area you create for the company. Steel construction provides the largest architectural clear span on the market.

The span of the warehouse can step over 60 meters. There is no need to install any load-bearing poles or columns inside the building. It makes it easy to set up large-scale industrial-scale equipment and machines, as well as vehicles and personnel to move safely within the structure.

Environmental friendly

Eco-friendliness is not just a trend. Data shows that building owners and customers who buy products and services are increasingly demanding green buildings. The steel structure is a sustainable building product because it uses recycled materials in the production stage and is 100% recyclable at the end of its service life.

Havit Steel Structure design and manufacture prefab steel building in China, which are used as the warehouse, workshop, and garage buildings.