3D printing is taking over the world in many ways. The technology has been hailed as the third technological revolution. 3D printing in construction is being used on items like concrete, masonry, and wood. Below are the 10 ways in which 3D printing is changing the construction industry but first, let’s look at three technologies used in 3D printing in construction.

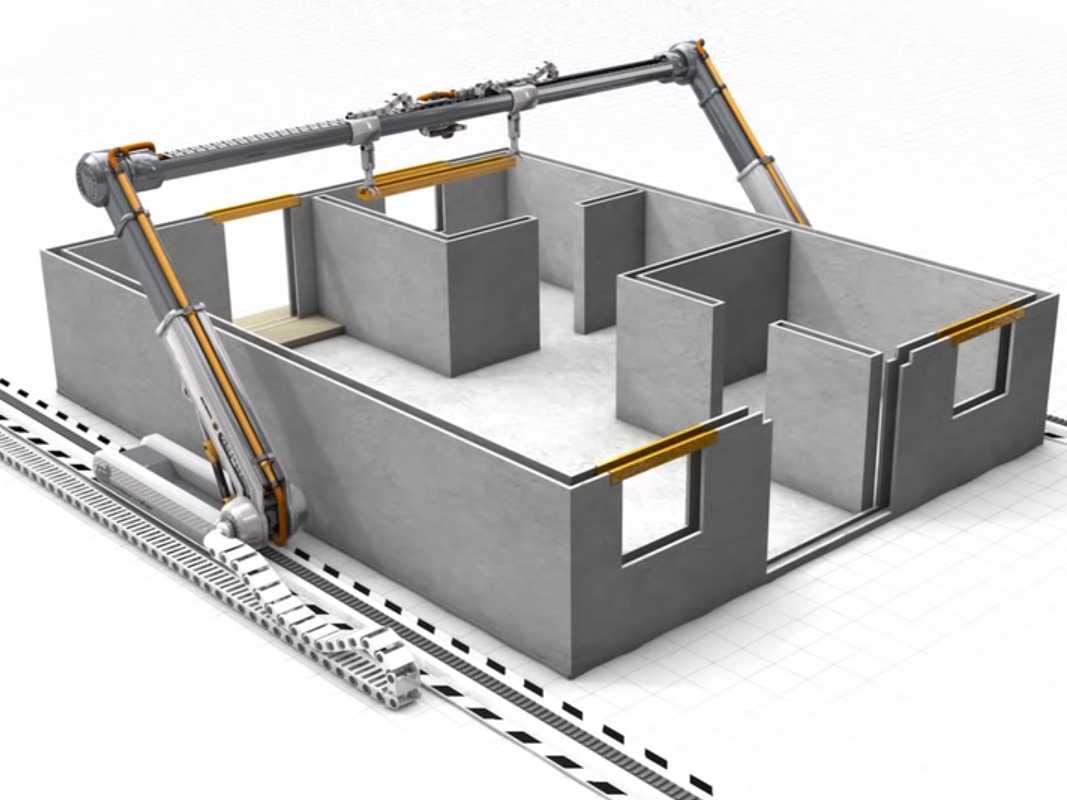

Robotic Arm Extruders

One of the key 3D printing technology being used in the construction industry is the robotic arm extruder whose working is similar to the FDM desktop 3D printer. The robotic arm moves on properly arranged rails, with the arm extruding concrete material from the nozzle to build various layers.

Sand 3D Printing

Sand 3D printing was first tested by Italian architect Enrico Dini, who later built his D-Shape 3D printer. Sand 3D printing is similar to industrial 3D Printing like SLS or Jet Fusion. This machine spreads a layer of sand powder and then uses a binder to harden the structure.

Metal Technology

Dutch company MX3D developed Wire Arc Additive Manufacturing (WAAM) used on structures like bridges that need to withstand a lot of pressure. The company used a mechanical robot working with a 3D printer that prints metals on 6-axis.

Advantages of 3D Printing for Construction

With the construction industry growing competitive every year, many contractors are turning to 3D printing to beat the stiff competition. Below are the top advantages of 3D printing in construction;

Reduced Injury

One of the biggest advantages that 3D printing has brought to the construction industry is reducing injuries while in the field. With 3D technology, construction workers have enough time to do their work and employees have fewer workers compensation paperwork.

Reduced Material Costs

3D technology helps workers to reduce material waste as they use the precise amount of concrete. This considerable reduction in waste enables companies to cut on the cost of materials. This way, builders and general contractors do not have to buy supplies in bulk as they know the exact amount needed. This is more environmentally friendly, more sustainable, and leads to the reduced total cost.

Faster Construction

Concrete 3D printers have set themselves apart for offering faster construction compared to traditional methods. 3D printers are able to complete a task much faster than traditional methods. Being able to finish faster allows contractors to move to other projects within a short period hence increasing revenue.

Crowd-Sourced Printing

The widespread use of 3D printers will allow companies to print from a service-based system. Having 3D printers as a software-as-a-service will help print any item. This is especially important in construction and architecture when it comes to design. 3D printing allows designers to create any shape by just feeding a digital blueprint of the specified item into the hardware.

Cheaper Construction

The use of 3D printers generally cuts costs compared to traditional methods and processes. This is mainly due to reducing the cost of materials and reduced injuries, which see construction companies see an increase in benefits. Workers who master technology get an opportunity to secure their jobs as they become specialists and consultants.

Commercial Development

3D printing is not used just for private and small projects. The technology is increasingly being rolled on a large scale. Recently Dubai announced completing the 3D-printed office block in the world. The block is a full-scale commercial office that has people and operations inside.

Improved durability

3D printers are said to add to the sturdy of structure during the first stages of construction. Construction companies are focusing on durable structures as they require few repairs. This helps developers and construction companies to cut on construction and repair costs.