Solar photovoltaic (PV) plants are rapidly becoming the preferred choice for power generation across the globe. They are an environmentally sustainable alternative to conventional sources of energy, and their lower operational costs make them more economically attractive as well. However, the efficiency of solar PV panels is susceptible to a range of environmental factors, including soiling, which can lead to significant energy losses. This is why it is crucial to implement soiling monitoring systems in solar PV plants.

How does the Soiling Affect the Performance of a PV Plant

The extent of the soiling problem depends on several factors such as the location of the solar project, the surrounding environment, the weather conditions, and the type of solar panels used. For instance, solar projects located in desert areas are particularly prone to the soiling problem due to the high levels of dust and sand in the air.

Soiling is the accumulation of dust, dirt, and other particulates on the surface of solar panels, which reduces their efficiency by reducing the amount of sunlight that reaches the cells. This can result in a significant drop in energy generation, which can have a negative impact on the overall performance of the plant. In fact, research has shown that soiling can cause energy losses of up to 50% in some cases. Actually, Soiling has a direct effect on the power generation in PV systems. In other words, a 10% soiling ratio means 10% of power loss. This is why it is essential to implement monitoring systems to detect and mitigate the impact of soiling.

The Importance of Soiling Monitoring Systems in Solar PV Plants

Soiling monitoring systems are a critical component of any solar PV plant. They offer a range of benefits, including increased efficiency and reduced maintenance costs. By monitoring the accumulation of dirt, dust, and other debris on solar panels, these systems help plant operators identify when cleaning is necessary. This enables them to clean the panels proactively before soiling reaches levels that can impact energy production.

In addition to improving efficiency, soiling monitoring systems can also help reduce maintenance costs. By enabling operators to target cleaning efforts only where they are needed, these systems minimize the amount of time and resources spent on cleaning. This is because cleaning the entire solar PV plant can be a very time-consuming and costly process.

How Does SEVEN Soiling Sensor Work

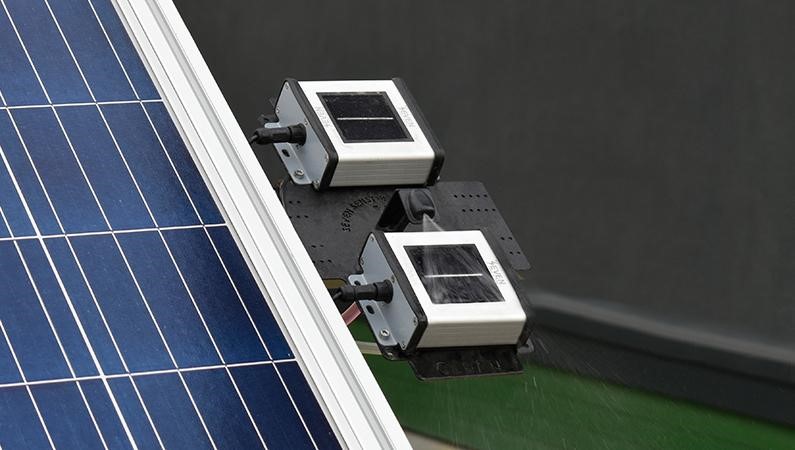

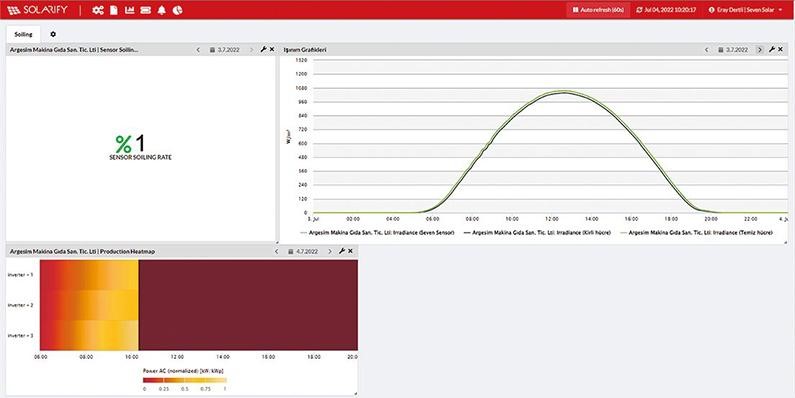

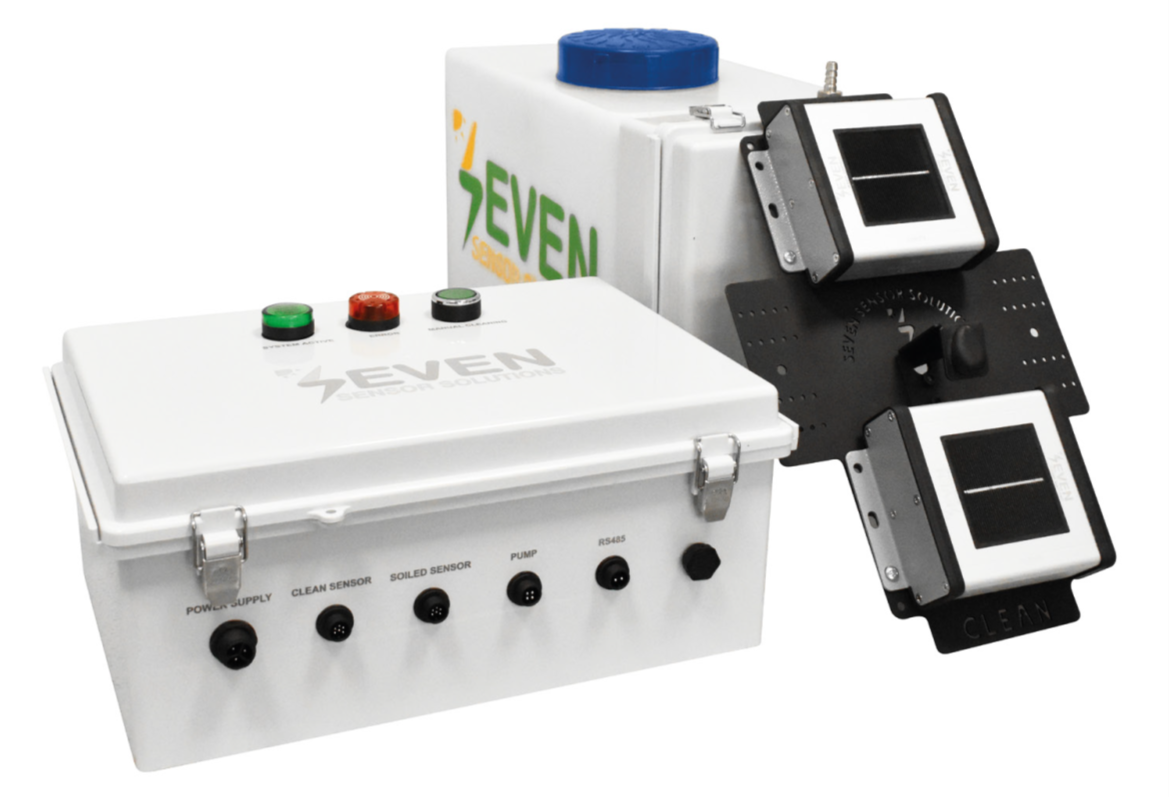

SEVEN has developed the Soiling Monitoring Sensor in accordance with the Standard IEC61724-1. It calculates the Soiling Ratio by comparing the irradiance values of two irradiance sensors; the first one is cleaned periodically and the other one is cleaned at the same time as the panels. The average soiling ratio is calculated daily by considering the irradiance values received in the noon period defined by the standard.

The soiling ratio can be monitored remotely by connecting SEVEN Soiling Sensor to the available monitoring system in the plant via Modbus RTU protocol. SEVEN Soiling Sensor is compatible with many well-known brand dataloggers as well as all PLC & SCADA systems supporting RS485. In addition, it is SunSpec compliant as well.

As previously mentioned, one of the irradiance sensors needs to be cleaned periodically. Since manual cleaning may be hard for difficult-to-reach locations such as rooftops, SEVEN developed the Automatic Soiling Sensor model which allows the cleaning of the irradiance sensor automatically and in the set time as per the site conditions and calculation periods. The automatic cleaning is performed by a jet of water installed above the sensor and connected to a tank of water with a capacity of 18 lt. This capacity is enough to run the system for 6 months. The used cleaning water must be pure water and antifreeze must be added for cold areas as per SEVEN datasheet and user manual.

Why to Use SEVEN Soiling Sensor

There may be different tools in the market to calculate the soiling ratio of PV plants. However, according to the research, soiling affects directly the amount of sunlight that reaches the solar cells. So, this means that the most accurate method of soiling ratio calculation would be by using two irradiance sensors which are providing the amount of solar radiation that reaches a particular area.

The Irradiance Sensors used in SEVEN Soiling Sensor are calibrated and tested before being dispatched to the project site. A calibration certificate is provided by SEVEN Sensor for all its sensors. A third-party certificate can be also provided upon the request of the client.

To sum up, soiling is a common problem in solar projects that can significantly reduce the efficiency of the solar panels, as it reduces the amount of sunlight that is absorbed by the solar panels and hence, reduces the amount of electricity that can be generated. Thus, using the soiling monitoring sensor is a must to be able to monitor the performance of the PV plant and keep it high.