Currently, there are about two dozen countries in Africa with an average power capacity of 200 megawatts each leaving some 620 million people without electricity. Another 25 countries in sub-Saharan Africa are facing frequent blackouts without any elaborate back-up power system. Although the African continent is well endowed both with fossil fuels and renewable resources, these are not evenly distributed, creating windfall profits for some countries and exacerbating the crisis in others.

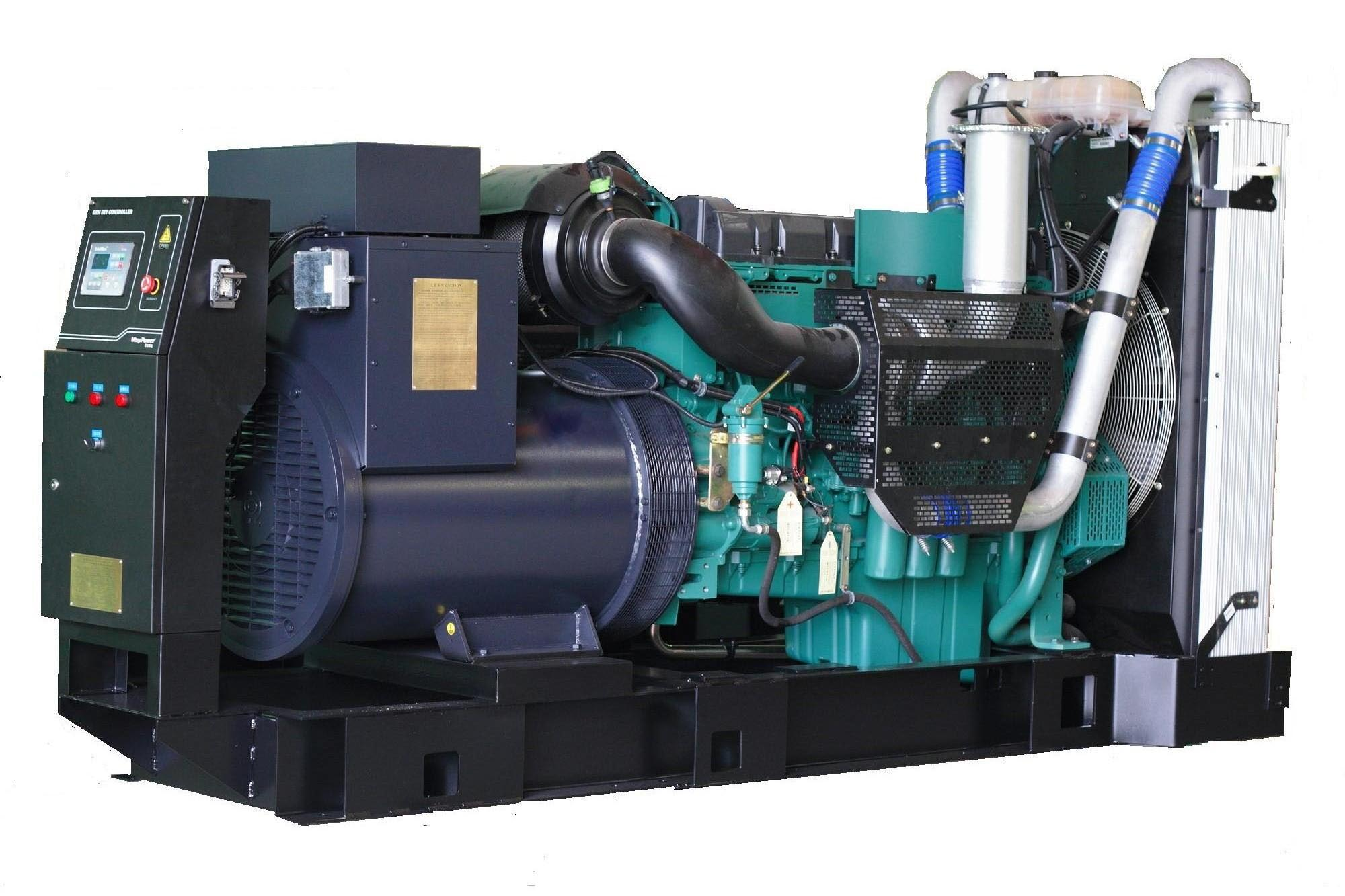

To dodge these shortcomings associated with on-grid power sources due to the production of insufficient electricity to cover the infrastructure development; Mr. Abdul Razak of OTC a generator supplier in the UAE says that, many people and businesses opt for generators mainly as back-up power options and in a few cases main power supplies for small installations. Whether the motive is meeting business needs or conforming to code requirements, most large organizations make generators part of the facility designs. But planning for back-up power is not so easy, and the sizeable investment that is involved makes it paramount that facility executives understand the key decision-making points in a generator project.

According to Ghulam Rasool the Sales and Technical Manager at Dubai’s Adpower a supplier of off-grid power requirements for construction, telecom, rail and oil and gas industries in the MENA region, getting a generator that can handle all your power needs is one of the most critical aspects of the purchasing decision. Whether you are interested in prime or standby power, if your new generator can’t meet your specific requirements then it simply won’t be doing anyone any good because it can put undue stress on the unit and even damage some of the devices connected to it.

“Unfortunately, determining exactly what size of generator to get is often very difficult and involves a number of factors and considerations which includes your total load requirements, the place where it has to be installed and its effects on environment. Recent developments in the generator manufacturing industry has made the generators environment friendly by reducing the emissions, high exhaust temperatures and sound levels,” he adds.

Also Read: Getting the best out of your diesel generator

Documenting the load

The first step is to identify what the generator will power. Every building that has a generator will have two types of loads: loads whose codes require emergency power and those for business-critical systems. Each of the loads must be documented appropriately.

Life safety code requires its branch of the emergency power system to be picked up by the generator within 10 seconds of utility failure. The critical branch in medical facilities also has the same 10-second requirement.

Upon completion of documentation, an engineer can size the generator and transfer switches. This sizing will indicate the physical and electrical requirements, which in turn affect the location of the generator.

Picking the right location

A second crucial step for facility executives is deciding the appropriate location for the generator. Generators are more often located outside than inside the building, but both locations have pros and cons. A third option is placing a generator in a penthouse or on the roof.

According to Saqib Nadeem of AT Generators a leading supplier of Diesel Generators in the UAE, it is very important to pick the right location for the generator for technical specifications purposes.

The decision to locate a generator outdoors raises issues specific to each facility. If visibility is an issue, for example, a generator can be located behind a screen wall or landscaping. However, this can cause security problems in some areas.

Climate plays a big role as well. In case solid screen walls are used, the area near a generator must be large enough to allow for adequate cooling in hot weather

Every generator needs to be kept warm conditions so that it can start up and take on the code-required loads in 10 seconds. In cold climates, putting a generator indoors helps keep the unit at starting temperature without oversized heating elements. Despite this advantage, indoor generators call for extra precautions. Due to the fact that they will store some fuel and may contain the transfer switches and panels for the emergency system, generator rooms should be fitted with a two-hour fire rating and may require a sprinkler system. Indoor generators may also cause special noise and vibration problems.

Locating a generator on the rooftop or in a penthouse can be advantageous in flood prone areas. A penthouse also keeps the unit at starting temperature in cold climates. However, height can amplify vibration, and the costs of meeting structural requirements should not be overlooked.

Controlling noise and vibration

This involves reducing vibration and noise Outdoor generators can sometimes be placed far enough away from a facility and help reduce the problem of noise. However, smaller sites may not offer the luxury of space for this, and even for larger facilities, the best screening area may be located near to the building.

Ms. Hilal Barutcu the General Manager of U Power International a provider of machinery and equipment from the construction industry to the oil sector in Turkey and the Middle East region mentions that, like many types of rotating machinery, reciprocating engine-powered generator sets produce noise and vibration. Whether these generator sets run continuously in prime power applications or only occasionally in standby applications, their operating sound levels often must be reduced. Generator set noise is produced by six major source; engine, alternator, cooling fan, induction, engine exhaust,mechanic and structural noises.

In residential areas the location of the generator is very critical. Many residential areas have noise limit ordinances in effect that are more restrictive compared to commercial areas.

An outdoor generator located close to a building has the same effects to one placed indoors. Significant effort must be made to manage the noise generated, and the first line of noise mitigation is the most basic: Keep the most sensitive occupants furthest way from the source of the noise. The space adjacent to a generator can be utilized for storage purposes, or other purposes that are not frequently occupied by people.

Another thing to consider is that the noise does not emanate from a generator in all directions equally. Manufacturers of sound-attenuating enclosures provide data to help orient a generator for maximum noise control.

“U Power International prevents all these noises with careful design, acoustic barriers and exhaust silencer at all type generator sets,” adds Ms. Barutcu.

Keeping up with the details

This entails addressing other switch and exhaust details in a generator project that should not be ignored.

The generator feeds into one or more transfer switches so as to distribute the power it produces. For indoor generators, this can be done in the same room. Outdoor units need to feed into a transfer switch room that is separate from the utility electrical room.

Facility mangers also need to put into consideration potential problems from the exhaust. The risk of exhaust gases finding their way into the HVAC air intake can cause problems for all generators, but that’s specifically true for roof-mounted units. The bigger the building, the bigger the generator and HVAC air intake — and the bigger the potential problem. Apart from careful design, exhaust piping and adsorption filters are two ways to prevent the problem.

Hi,

Really happy to say your post is very interesting to read. I never stop myself to say anything about it. You’re doing a great job. Keep it up. We are one of the best-selling generator maintenance company in UAE with a wider presence all around the globe. Our products are the most cost effective solution and are of the strongest quality. Expecting more blogs.

Nice article I found this is very informative information. thanks for sharing.