There is a huge demand for sealants and adhesives in the construction industry with increasing consciousness of effective water proofing in buildings.

Sealants and adhesives come into play when materials have to be joined to make components. Which joining technique is able to join these materials? This question arises always when deciding on the bonding technology.

There is a thin line between adhesives and sealants, which makes it difficult to pick out the difference between the two. They share similarities when it come to the material used in production and on applications.

An adhesive is a substance that is capable of holding at least two surfaces together in a strong and permanent manner, while a sealant is a substance capable of attaching to at least two surfaces, thereby filling the space between them to provide a barrier or protective coating.They both have the capacity to seal and adhere, they are resistant to the operating environments and their properties are highly dependent on how they are formulated and applied.

Common characteristics shared by adhensives and sealants

• When they are applied the act as a liquid in order to flow over and wet the substrate surface.

• The attach surface through adhesion.

• They must harden to carry sometimes continuous, sometimes variable, load throughout their service life.

• They transfer and distribute load among the components in the joint.

• They fill gaps, cavities, and spaces.

• They work with other components in the joint to provide a durable product.

Adhesives are chosen for their holding and bonding power. They are generally materials of high shear and tensile strength when used in structural applications or high peel strength and tackiness when used in non-structural applications.

Sealants are generally chosen for their ability to fill gaps, resist relative movement of the substrates, and exclude or contain another material. They are generally lower in tensile strength than structural adhesives, but have better flexibility.

Sealant formulations contain elastomeric resins to provide flexibility and elongation rather than tensile strength. Sealant formulations also contain relatively large amounts of inert filler materials and extenders. These contribute to cost reduction, rheology modification, and gap filling.

Bonding technologies

Ecotak is a pliable preformed recycled EVA 60 mil thick film with bio-based adhesive backing that exhibits exceptional adhesive properties. Ecotak’s non-bitumen based adhesive is derived from canola oil. This bio-based adhesive adheres the Ecotak membrane to various substrates better than many traditional bitumen based adhesives.

The pliable EVA film offers superior puncture resistance and tensile strength while also providing excellent chemical resistance. Performance: zero compromise, 2x the Elongation, 3x the Puncture resistance, and 4 x the Adhesion to concrete.

Exceptional adhesion. Bio-based adhesive adheres to substrates more tenaciously than typical bitumen based adhesives ensuring superior waterproofing performance. Since it is a bio based adhesive, naturally derived from canola oil, Ecotak’s bio-based adhesive is free of bitumen based compounds and applies to green concrete and allows for fast application.

Eliminate the 28 day delay and apply the Ecotak system as soon as the concrete substrate is structurally sound. It enjoys superior physical strength, durability and flexibility. EVA (ethyl vinyl acetate) is a highly durable polymer that offers excellent protection required for a high performance waterproofing membrane while maintaining flexible workability for ease of application and has LEED credits. Ecotak EVA film is not only exceptionally durable but also comprises of over 20% recycled content.

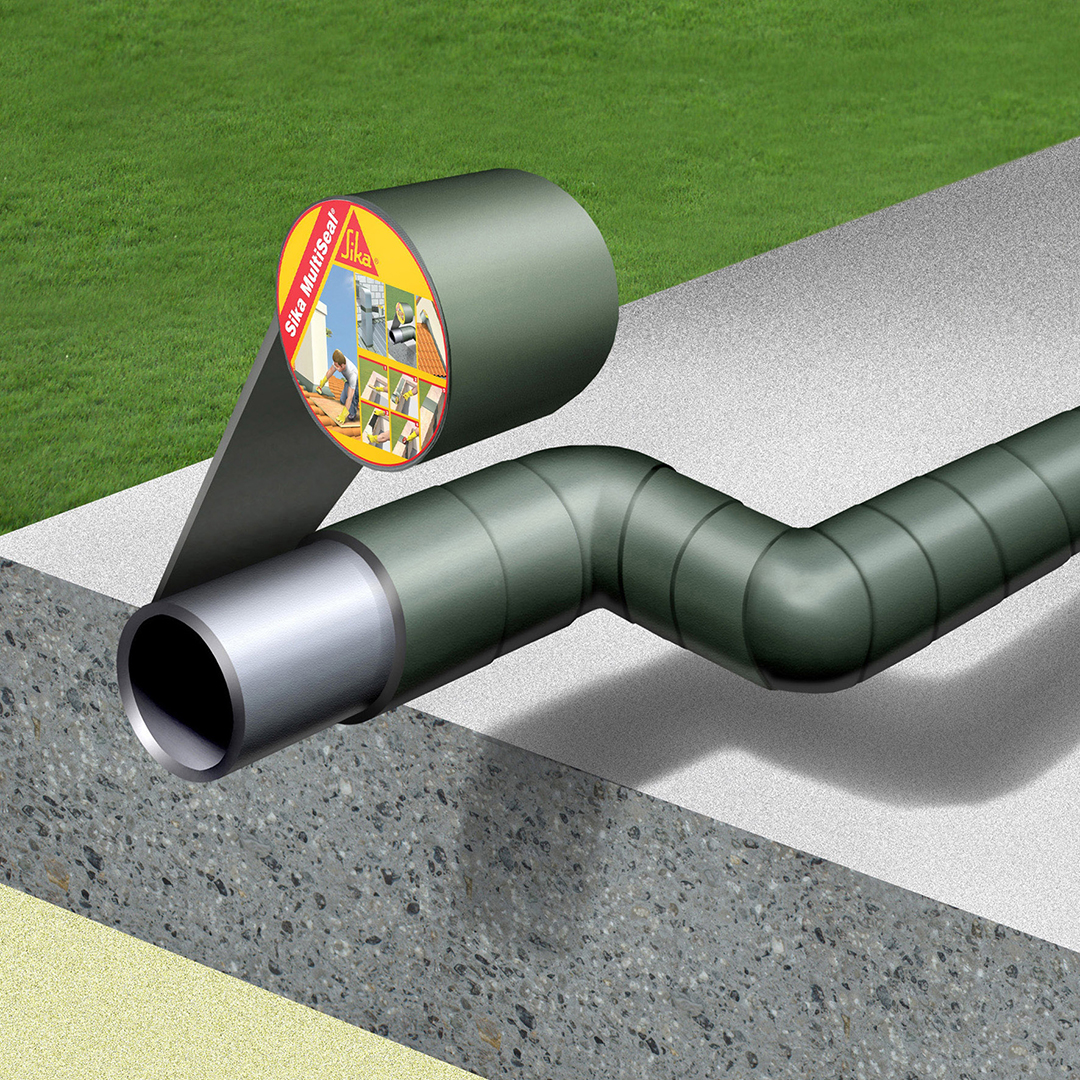

Sika launched MultiSeal-ZA in SA

Sika MultiSeal-ZA is a self-adhesive, bituminous sealing tape with one side laminated with aluminium foil. This handy DIY product is an ideal, quick-fix solution for sealing and repair against water ingress and draughts in roofs, including sheet metal work, building cracks, inside of gutters, bituminous felts and other types of roofing sheet.

Sika MultiSeal-ZA is UV resistant, very easy to apply, economical, weather-proof and it can be over-painted. It allows easy adhesion to many substrates, is bitumen-resistant, and can be applied at low temperatures. Using it is easy: – simply clean the surface area, cut the tape to the necessary length, remove the release film and press the tape firmly onto the substrate with a suitable pressure roller. Due to market demand, Sika has launched this product in three new sizes: 50mm x 2.5m, 75mm x 2.5m and 100mm x 2.5m.

BASF Concresive ®1315

Concresive® 1315 is a two component crack injection fluid for repairing cracks in concrete. It can be injected into cracks of varying sizes including cracks too fine to be filled with traditional materials. A two components epoxy resin system based on low –viscosity resins.

Ideal for sealing static cracks from widths greater than 100 microns but no more than 9mm. It is highly penetrative and cures to form a permanent seal against the ingress of corrosive fluids and gases and is capable of restoring integrity to structural elements.

The 1314 can be used to fill and bond static and dormant cracks in columns, Bridge decks, floors, piers, tunnels, basements, beams and underpasses.

Major differences between sealants and adhesives are how they are regarded relative to appearance, chemical effects, and joint design. These characteristics are also important to adhesives in certain applications, but they are often found in sealant specifications. Adhesives and sealants are chemical products and care should be taken during use and storage to avoid contact with eyes, mouth, skin and foodstuffs.