In an industry defined by scale, complexity, and risk, the need for precision and safety is non-negotiable. Modern oil and gas operations stretch across remote fields, offshore rigs, and urban refining plants, each site demanding real-time visibility, stable operations, and tight compliance. Meeting these expectations has led to widespread adoption of industrial control and automation technologies, with advanced systems now embedded across upstream, midstream, and downstream operations.

The oil and gas sector has always relied on efficiency and safety to stay competitive. Today, new advances in control systems integration for oil and gas industry operations are helping companies streamline processes, cut downtime, and improve decision-making. Automation isn’t replacing human oversight; it’s enabling safer, leaner, and more predictable operations in environments where error is costly.

Automation in Exploration and Drilling

Drilling operations involve high-risk, high-cost decisions where precise timing and pressure control are crucial. Automating this phase reduces the margin for error while enhancing worker safety. Systems, such as automated drilling rigs, can adjust parameters like rotation speed and mud pressure in real-time based on geological feedback.

Advanced automation tools now enable predictive planning, with geological modeling systems feeding real-time seismic data directly into the control interface. This not only accelerates drilling timelines but also reduces non-productive time (NPT) by preventing unnecessary stoppages or manual recalibrations. Even remotely controlled rigs are increasingly deployed in hazardous environments, thereby minimizing human exposure.

Process Control in Refining and Petrochemical Plants

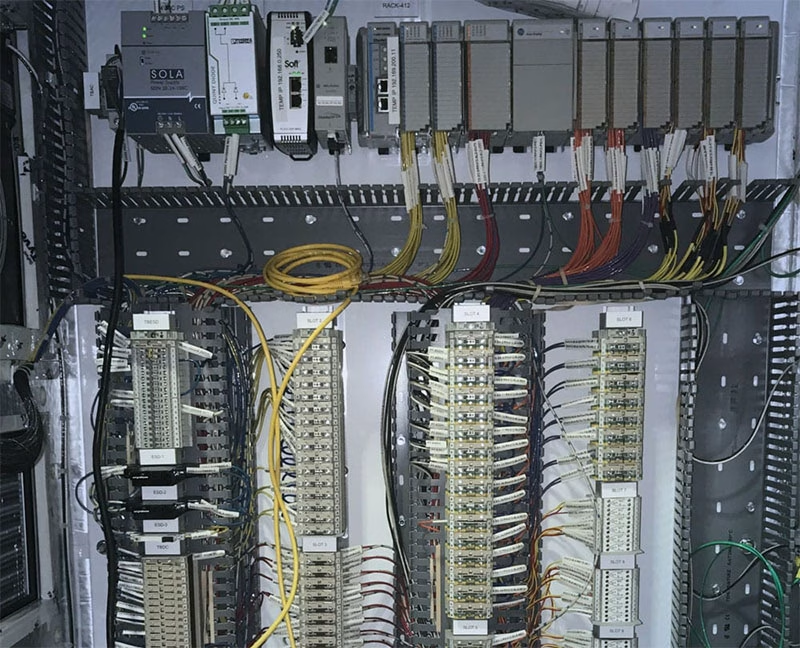

Once crude oil reaches the refining stage, control becomes even more critical. Thousands of interconnected processes, ranging from distillation to hydrocracking, must operate continuously, often at high temperatures and pressures. Distributed Control Systems (DCS) play a central role in managing flow rates, chemical concentrations, and energy loads across each unit.

The integration of control systems enables operators to visualize process deviations immediately. For example, sensors might detect pressure imbalances and automatically trigger alarms or initiate partial shutdowns before equipment is compromised. These systems are often linked to safety instrumented systems (SIS), which act as fail-safes in emergency scenarios.

Pipeline Automation and Midstream Monitoring

Midstream infrastructure pipelines, terminals, and storage facilities benefit significantly from automation. SCADA (Supervisory Control and Data Acquisition) systems monitor long-distance pipelines for flow rates, leaks, and pressure anomalies. Operators can manage vast networks from centralized control rooms, thereby improving both responsiveness and cost efficiency.

Automation also helps reduce environmental risk. Leak detection algorithms can identify inconsistencies in flow data, allowing maintenance crews to address problems early. Valve actuation and pump scheduling can be performed remotely, ensuring supply chain continuity even during adverse conditions or labor shortages.

Enhancing Safety and Compliance Through Automation

The oil and gas sector faces some of the most stringent safety and regulatory standards in industrial operations. Control systems integration plays a critical role in meeting these standards by embedding automatic shutdown sequences, interlocks, and real-time audit trails within operational workflows.

Automation platforms can also log and timestamp every system change, supporting internal safety reviews and regulatory audits. Environmental monitoring tools track emissions and effluents, automatically adjusting operations to ensure compliance with legal limits. These capabilities not only support compliance but also reduce the administrative burden on HSE teams.

Data Integration and Operational Intelligence

The value of automation increases exponentially when it’s paired with smart data practices. Integrated systems can collect, organize, and contextualize data across drilling, processing, and transport assets. Instead of analyzing isolated datapoints, operators access actionable insights through centralized dashboards and cloud analytics.

By merging historical trends with real-time feedback, control systems support asset integrity management, performance benchmarking, and predictive maintenance. This integrated intelligence enables better budgeting, faster root cause analysis, and more confident long-term planning. In effect, automation becomes a strategic asset, not just a technical upgrade.

Remote Operations and Workforce Optimization

Geographic isolation has long been a significant barrier in the oil and gas industry. Many facilities operate in harsh or inaccessible environments, where flying in teams for routine checks is both costly and risky. Automation has reshaped this reality. With remote operations centers powered by integrated control systems, a single team can manage multiple sites across different time zones.

Operators can receive alerts, view system metrics, and even control equipment without being physically present. This shift also supports leaner staffing models and better allocation of expertise. Instead of stationing highly trained personnel on-site 24/7, companies can centralize technical knowledge and deploy it more efficiently.

Future Trends in Automation Technology

As the sector adapts to cleaner energy goals and digital transformation, automation will continue to evolve. Edge computing and AI-driven control loops are gaining traction, enabling local decision-making with minimal latency. Cloud-based control interfaces are becoming more common, especially in midstream and refining operations.

Cybersecurity is also taking centre stage. As control systems become more connected, protecting them from breaches and downtime is crucial. Forward-looking operators are building cyber-resilient control architectures with segmented networks, regular patching, and real-time threat detection.