When metal parts go into long-term storage, rust doesn’t wait for permission—it quietly starts the moment moisture and oxygen get cozy on the surface. Whether you’re storing industrial components, automotive parts, tools, or machinery, corrosion can turn valuable assets into costly replacements if the right protection isn’t in place. That’s where rust inhibitors step in as the unsung heroes of preservation.

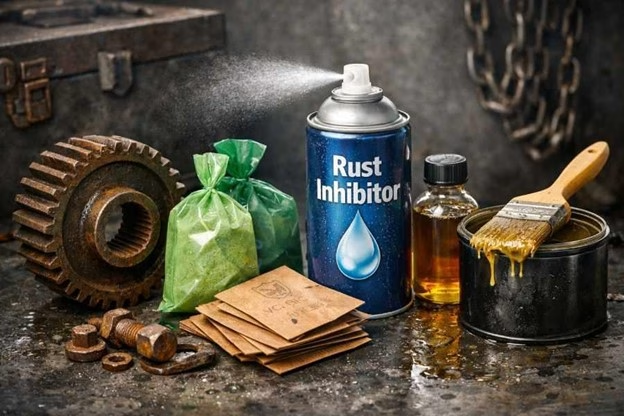

From moisture-displacing sprays that push water away on contact, to Vapor Corrosion Inhibitors (VCI) that form an invisible protective atmosphere, to durable film coatings that seal metal surfaces for months or even years—modern rust prevention technologies offer targeted solutions for every storage challenge. Choosing the right inhibitor isn’t just about stopping rust today; it’s about ensuring your metal comes out of storage in the same condition it went in.

In this guide, we’ll explore the top rust inhibitors for long-term storage, break down how moisture displacement, VCI protection, and film coatings work, and help you decide which approach delivers the best balance of protection, cost, and convenience for your specific needs. Explore further information at australianinhibitor.com.au

Why Metals Rust in Storage and How Inhibitors Prevent It

In storage, metals corrode when oxygen, moisture, and contaminants meet on metal surfaces. Humidity cycles drive condensation; salts and acids (from fingerprints, packaging, or marine air) accelerate electrochemical reactions. Dissimilar metals in contact add galvanic risk. A well-chosen rust inhibitor interrupts this chemistry by creating barriers, displacing water, passivating the surface, or saturating the package headspace with protective vapor.

Effective rust prevention blends corrosion protection with practical handling: clean parts, dry environments, and the right corrosion inhibitor for the metal, duration, and conditions. Across automotive, industrial, and marine settings, the goal is consistent metal protection and dependable rust control without complicating maintenance or operation later.

Moisture-Displacement Inhibitors: How They Work

Moisture-displacement products are solvent-borne fluids that chase water out of crevices and leave a thin, hydrophobic film. A waterproof lube in this category often doubles as a light lube and anti-rust spray: it creeps into seams, under fasteners, and inside threads to protect metal and prevent rust. The film provides surface protection and corrosion resistance by blocking oxygen and brine. Many are multi-purpose, easy to apply, and ideal for short to mid-term storage where equipment may need to be put back into service quickly.

These are popular for gear care on tools, hardware, automotive assemblies, and outdoor equipment. A high-quality moisture-displacing rust inhibitor can be a first line of defense prior to bagging parts or wrapping with barrier film.

Pros

- Water-chasing action plus light lube for moving parts; great for quick rust prevention in automotive and machinery.

- Penetrates tight clearances; an anti-rust spray can reach areas a brush-on protective coating cannot.

- Typically easy to apply, non-messy, and compatible with follow-on lubrication.

Cons

- The film can be thinner and less long-lasting than waxy film coatings; periodic reapplication may be needed.

- Some formulas attract dust or are not ideal under heavy washdown or marine splash.

- Not all are non-toxic; check SDS for professional use requirements.

Ideal Use Cases

- Short- to medium-term storage protection of assembled equipment and vehicle parts.

- Interim rust & corrosion control after a rust remover, before final rust proofing.

- Inside enclosed housings where an anti-rust lube can stay put yet be cleaned off easily at restart.

Moisture-Displacement Picks and Buying Notes

Look for waterproof lube sprays that specify corrosion protection timeframes and salt-spray test data. Boeshield T-9 is a well-known boeshield formulation that displaces moisture and dries to a waxy protective coating—popular for tools, bikes, marine rigs, and automotive hardware. On Amazon, you’ll find options in Automotive and Home Improvement; check Best Sellers lists, reviews, and whether Prime shipping is available. Amazon Basics offers budget-friendly, multi-purpose spray options, while premium brand choices target professional use and aftermarket maintenance.

If you’re organizing a shop wish list, add items via Amazon Home or a Registry; many users share their Amazon Haul and feedback. When browsing, note you’ll encounter categories like Music, Books, Smart Home, and Kindle Books—those are unrelated; likewise, Amazon Pharmacy is not where corrosion inhibitor products are cataloged.

VCI Papers, Emitters, and Bags: Mechanisms Explained

VCI (volatile corrosion inhibitor) technology releases corrosion-inhibiting molecules that vaporize and adsorb onto metal surfaces, forming an invisible, molecular barrier. In a closed volume—bag, box, or crate—the vapor-phase shield ensures corrosion protection even in voids and threads. VCI papers wrap parts; emitters treat cabinets; bags seal assemblies. Because the inhibitor replenishes in the headspace, VCI excels at rust prevention for complex geometry, electrical panels, and spare-parts kits. Most modern VCI chemistries are dry-to-the-touch and non-toxic, making them easy to handle for both industrial packaging and home improvement projects.

VCI Setup Best Practices

- Use clean, dry parts; wipe with solvent or a rust remover if needed.

- Choose VCI matched to your metal (ferrous, copper, aluminum) for best corrosion resistance.

- Line boxes with VCI paper, then wrap parts fully—avoid direct contact between dissimilar metals.

- Use the correct VCI emitter/bag volume rating; overdo rather than underdo for long-lasting coverage.

- Seal packages tightly; add desiccant in humid or marine environments for stronger storage protection.

- Avoid oils that can block VCI adsorption unless the manufacturer says they’re compatible.

Film Coatings and Barrier Wraps: Options and Longevity

Film coatings leave a thicker, often wax-like layer designed for long-term metal protection. Examples include wax/oil blends, polymer films, and specialty anti-rust coatings formulated for automotive chassis, machinery, and marine spares. Boeshield T-9 can serve as a film-former after drying; heavier-duty products are brushable or spray-applied and cure to a tack-free barrier. These provide excellent corrosion resistance and rust control for months to years, depending on thickness and environment. Pairing a film coating with a sealed barrier wrap multiplies rust prevention performance.

Packaging Strategies with Barrier Wraps

Barrier wraps (poly laminates, aluminum-foil composites) block moisture ingress; when combined with desiccant and VCI inside, they create a microclimate. Strategies include:

- Apply a film coating, let cure, then bag with VCI and desiccant.

- Heat-seal or tape seams to minimize vapor transmission.

- For marine or tropical storage, double-bag and include humidity indicator cards.

- For vehicle parts and outdoor equipment, isolate rubber/plastic where solvents might migrate.

Selection and Application Guide: Match to Metals, Environments, Duration

- Metals: Ferrous parts respond well to VCI and film coatings; copper/brass need VCI formulated for yellow metals; aluminum benefits from neutral pH inhibitors.

- Environments: Marine or salt-laden air favors film coatings plus sealed barrier wraps; industrial indoor storage often succeeds with VCI bags; automotive garages can rely on waterproof lube sprays for rotating spares.

- Duration: Weeks to 3 months—moisture-displacing lube spray. 3–12 months—VCI bags plus occasional reapply of anti-rust lube. 12+ months—film coating, VCI, and barrier wrap for robust rust proofing.

- Re-entry: Choose easy to apply, clean-removable systems when frequent maintenance or inspection is required.

Prep Before Storage: Clean, Dry, Inspect

- Degrease: Remove shop soils that trap moisture; use a compatible cleaner or rust remover if flash rust appears.

- Dry: Warm-air or solvent displacement; avoid trapped rinse water in cavities.

- Handle: Wear gloves to protect metal surfaces from fingerprints; label assemblies and cap open ports.

Application Techniques for Sprays and Lubes

- Use a straw nozzle to direct spray into seams, threads, and tight recesses.

- Let a waterproof lube creep, then wipe excess; reapply a thin film for consistent coverage.

- For larger machinery or vehicle assemblies, fog with a compatible lube spray to coat internal volumes.

- Confirm compatibility with downstream lubricants and torque specs before professional use.

A high-grade rust inhibitor lube that’s easy to apply helps protect metal while simplifying recommissioning. In automotive work and aftermarket parts storage, repeat a light anti-rust spray after any handling.

Combining Methods for Redundant Corrosion Protection

Layering increases reliability:

- Moisture-displacing waterproof lube inside, VCI wrap outside, barrier bag as the final shell.

- For critical spares and tools, film coating plus VCI emitters in a sealed cabinet delivers long-lasting storage protection.

- In marine settings, add desiccant and humidity indicators to verify package integrity.

Monitoring, Reopening, and Re-Treatment

- Inspect seals and indicator cards quarterly in humid locales.

- On reopening, wipe off dust, refresh the rust inhibitor, and replace VCI papers or emitters.

- Log maintenance intervals for machinery and equipment to keep rust & corrosion at bay.

Special Cases: Electronics, Optics, and Painted Parts

- Prefer dry VCI for circuit boards and controls; avoid oily lube films unless specified.

- For optics and coated finishes, use non-staining VCI and breathable covers; skip aggressive sprays.

- Painted automotive components still benefit from VCI in boxed storage to protect edges and fasteners.

Safety, Environmental, and Handling Notes

Choose non-toxic formulations when possible and review SDS for ventilation and personal protective equipment(PPE). Dispose of wipes and desiccants properly. For home improvement users, keep sprays away from ignition sources; for industrial sites, standardize on a premium brand with documented test data to support audits. Whether you buy from Amazon or local distributors, verify category placement (Automotive or Home Improvement), check Best Sellers and Prime availability, and compare Amazon Basics against specialized products for value. Ultimately, the right corrosion inhibitor system—moisture displacement, VCI, film coatings, or a blend—delivers dependable rust prevention, robust corrosion protection, and practical metal protection across tools, hardware, machinery, vehicles, and outdoor equipment.