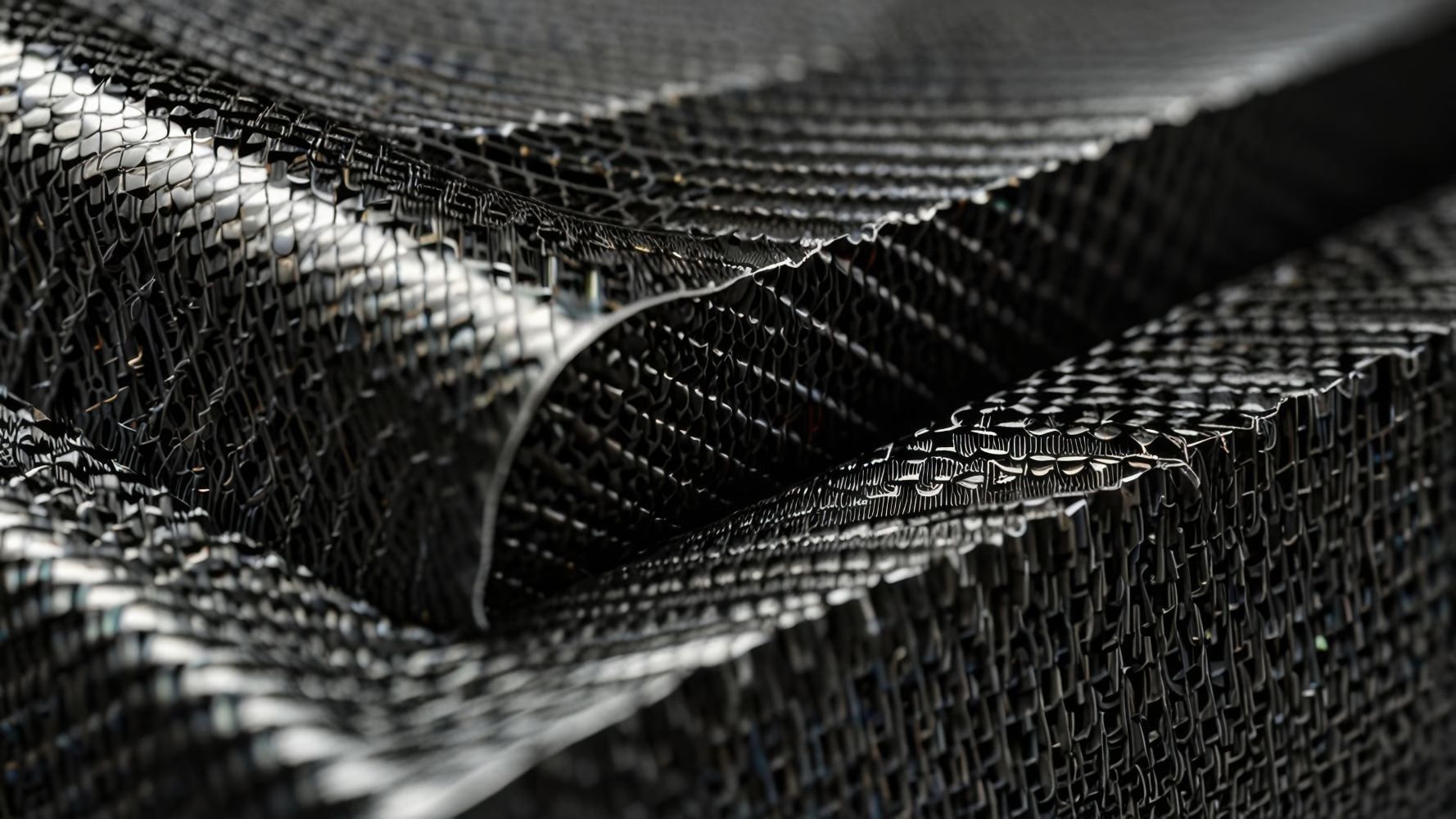

Epoxy coated wire mesh represents a significant advancement in construction materials, offering enhanced durability and longevity compared to its uncoated counterparts. The primary advantage of utilizing this specialized epoxy coated wire mesh lies in its formidable resistance to corrosion, a critical property for demanding environments. This material consists of a steel wire grid that’s uniformly coated with a layer of epoxy resin, a thermosetting polymer known for its exceptional adhesion, hardness, and chemical inertness.

The fusion of the firm, flexible steel core with the protective epoxy layer creates a composite material ideally suited for applications where exposure to moisture, chemicals, and physical stress is a constant concern. Its versatility can make it an indispensable component across a wide spectrum of construction projects.

Here are the top uses of epoxy coated wire mesh in construction:

Reinforcing Concrete Structures

One of the most prevalent applications of epoxy coated wire mesh is in the reinforcement of concrete. When embedded within a concrete pour, the mesh acts as a tensile backbone, countering concrete’s inherent weakness in tension. The epoxy coating is paramount in this role, particularly in environments prone to causing corrosion in reinforced concrete. Chlorides from de-icing salts, prevalent on bridges and roadways, or from marine atmospheres in coastal buildings, can penetrate concrete and attack uncoated steel. This corrosion can lead to expansive forces that cause the concrete to crack and spall, compromising the entire structure.

Furthermore, epoxy coating, such as those found in products from Epoxy Coated Wire Mesh, acts as an impermeable shield, preventing chloride ions and moisture from reaching the steel. This proactive defense can mitigate the primary cause of concrete degradation, thereby significantly prolong the structure’s service life and reduce long-term maintenance costs for critical infrastructure.

Creating Secure and Durable Partitions

In architectural and commercial design, using specialized forms of wire mesh, such as metal mesh, can be a great idea as it expands far beyond its industrial applications. It’s commonly specified for balcony infills, stair railings, and decorative interior or exterior screens, where its combination of strength and transparency is highly valued.

A significant aesthetic advantage is the ability to incorporate various colors directly into the epoxy coating during the manufacturing process. This feature allows the mesh to be seamlessly integrated into a building’s design scheme, fulfilling both functional and visual roles without compromising its protective qualities.

The result is a versatile architectural solution that offers security and spatial definition without the visual bulk of solid walls. Lastly, it can guarantee a long-lasting, maintenance-free finish that reliably withstands environmental exposure, from urban pollution to coastal salt spray, ensuring the architectural vision endures for decades.

Specialized Applications in Construction

The unique properties of epoxy coated wire mesh lend it to several specialized niches of the construction industry. In masonry and stucco systems, it’s embedded as a reinforcing layer to control cracking and add impact resistance to walls. The coating can help prevent rust stains from bleeding through the finished surface, a common problem with uncoated mesh.

Moreover, the material is indispensable in the construction of reinforced earth structures, such as retaining walls and slopes. Here, layers of mesh are placed within the compacted soil, where their corrosion resistance is vital for long-term stability. The mesh interacts with the soil, creating a stable, coherent mass that can resist lateral earth pressures far more effectively than unreinforced soil.

Infrastructure and Landscaping Uses

Large-scale infrastructure projects heavily rely on the durability of epoxy coated wire mesh. It’s used in the construction of tunnel linings, where groundwater and environmental chemicals pose a constant threat. It also finds application in marine structures, such as seawalls and piers, where resistance to saltwater is non-negotiable.

In the field of landscaping and civil works, the mesh is employed in gabion baskets. These wire cages, filled with stone, are used for erosion control, retaining walls, and landscape features. The epoxy coating ensures that these baskets will not deteriorate prematurely when exposed to stream flow, acidic soils, or weather, thereby maintaining the structural integrity of the installation for decades.

Final Thoughts

The integration of epoxy coated wire mesh into construction projects is a testament to the industry’s continuous pursuit of durability and performance. Its role extends far beyond simple reinforcement, touching upon aspects of longevity, safety, and aesthetic flexibility.

By keeping the information mentioned above in mind, construction companies can ensure that concrete remains sound, partitions stay secure, and infrastructure withstands the test of time and environment. As construction standards evolve to demand more resilient and sustainable solutions, the use of epoxy coated wire mesh is poised to remain a fundamental practice for engineers and builders aiming for excellence and longevity in their creations.