Lumber prices have finally cooled, U.S. housing starts are trending up again, and the timber-construction market now tops $16 billion—growing almost 10 percent each year. Prefab, CNC-cut timber-frame kits turn that momentum into on-site savings: numbered beams slash measuring time, crews raise walls in hours, and permit-ready shells dry-in within days. Today, frame-only bundles average $40–$50 per square foot and SIP-sealed shells hover near $150, while Canadian kits still cross the border duty-free under USMCA. In the pages ahead, we compare four nationwide suppliers so you can match speed, budget, and design freedom to your 2025 build.

How we picked the four kits you’ll see next

A timber frame house kit with SIP wall panels being assembled on site, illustrating modern prefab construction.

We began with eight nationwide timber-frame brands, then ran each through four must-have filters:

- Nationwide delivery. The company must ship a heavy-timber or post-and-beam kit to all 50 states, with no “call for availability” surprises.

- Current numbers. We asked for written 2024–2025 pricing and lead-time ranges and cut vendors that sent outdated or vague figures.

- Permit-ready engineering. Kits had to include engineer-stamped structural drawings most county offices approve on the first pass.

- Tiered packages. Buyers should be able to choose frame-only, SIP-enclosed shell, or near-turnkey bundles to control the budget.

Brands that cleared those hurdles were scored on five weighted factors: cost per square foot, what’s in the box, shipping speed, design flexibility, and sustainability support.

According to Hamill Creek Timber Homes design materials, clients receive a timber frame material package contract that breaks out material, engineering, shipping, installation, and payment schedule and locks in a price to either the framing or lock-up stage, with full turnkey available through its regional general contracting team.

The same process produces a single set of permit-ready construction drawings stamped by engineers licensed across U.S. states and Canadian provinces, so local inspectors and trades are working from the exact same plans.

The next four sections use that same yardstick so you can quickly see whether a budget-flexible, full-service luxury, high-performance shell, or fast-catalog kit fits your project.

Hamill Creek Timber Homes: Canadian craftsmanship that travels well

Since 1989, this family-run shop in British Columbia’s Selkirk Mountains has blended hand-cut mortise-and-tenon craft with CNC precision, then shipped frames from Hawaii to the Florida Keys. Today it offers three clear kit tiers:

- Frame-only – labeled timbers, steel plates, oak pegs, and permit-ready drawings for about $40–$50 / ft².

- Lock-up shell – adds factory-cut SIP walls (≈ R-24) and roof panels (≈ R-50), plus doors, windows, and roof decking, landing near $150 / ft².

- Turnkey – interior finishes and a local GC partnership push totals toward $300 / ft².

Hamill’s site also lists a wider $60–$90 / ft² average for custom frames, reflecting design complexity and timber species.

Production runs 4–6 weeks after you sign the drawings; crews raise the frame in 5–10 days, and a SIP enclosure can dry in within two weeks. Because the kits qualify under USMCA, they cross the border duty-free, and Hamill sets up lift-gate or crane delivery on arrival.

Sustainably harvested Douglas-fir and western red cedar leave the shop pre-sealed with a water-based UV coat, saving on-site finishing time.

Why choose it? Versatile pricing, artisanal joinery, and quick phone support suit owners who want bespoke timber aesthetics without breaking the budget. Trimming costs can be as simple as choosing abundant Douglas-fir over imported species and keeping rooflines compact – practical moves highlighted in Hamill Creek’s guide to budgeting for a timber frame home. Fully custom designs can extend lead times, and turnkey oversight outside the western states depends on partner availability.

PrecisionCraft Log & Timber Homes: design-build luxury in one contract

PrecisionCraft rolls architecture, engineering, and construction into a single “Total Home Solution.” M.T.N Design tailors a plan to your sun angles and snow load, then engineers the timber frame, SIP shell, and ICF foundation so every spline aligns on site.

The package sits at the high end of the market, but the scope is broad: free-of-heart-center Douglas-fir timbers, factory-cut Insulspan SIP walls (≈ R-26) and roofs (≈ R-40+), an ICF basement kit, and a company raising crew. Client reps say recent shell packages often start around $100–$140 / ft², with turnkey builds topping $500 / ft² depending on finishes.

Timelines run longer than catalog kits. PrecisionCraft’s blog outlines 8–12 weeks for design, 2–6 weeks for fabrication, and 1–3 weeks for on-site installation—about nine months from first sketch to materials delivery.

Because the envelope is continuous—SIPs above, ICFs below—many owners reach net-zero targets by adding solar only. A project manager stays aboard through final inspection, and the structural frame carries a 10-year warranty.

Bottom line: if you want a bespoke timber estate handled by one accountable partner, PrecisionCraft trades a higher buy-in for peace of mind and resort-level detailing.

Riverbend Timber Framing: high-performance shells without the guesswork

Riverbend has spent 40 years refining one product—the Base Package—and it still does the heavy lifting today. The bundle ships three engineered layers you can stack like Lego:

- Insulated concrete-form (ICF) foundation blocks

- A CNC-cut timber frame, erected by a Riverbend crew

- Pre-cut structural insulated panels (SIPs) for every wall and roof plane

While stick crews are still nailing exterior walls, a Riverbend shell is often under roof.

Cost snapshot

Riverbend doesn’t post flat square-foot pricing, but recent plan pages list structural-shell costs from $350 k to $675 k for homes between 1,000 ft² and 1,830 ft²—roughly $190–$370 / ft² depending on size and complexity. Those figures cover the timbers, SIP envelope, and on-site frame raising; you still budget separately for finishes and mechanicals.

Built-in efficiency

- SIP walls ≈ R-26 and 10-inch roof panels ≈ R-42

- ICF basement walls ≈ R-22 once poured

The continuous insulation cuts thermal bridging, so blower-door scores typically beat code.

Timeline and support

Riverbend schedules its raising crew during design; fabrication plus delivery generally lands in a 16- to 24-week window. The crew erects the frame in a few days and trains your builder on SIP installation. You keep design freedom—farmhouse, lodge, or modern concept—because their panel-plus-timber anatomy flexes around dramatic overhangs and hammer-beam trusses.

Know the trade-offs

Riverbend sells only the full shell, not frame-only kits. If you need a hybrid envelope, look elsewhere. But for builders who want one vendor, one crew, and an energy-smart shell that dries in fast, Riverbend removes a dozen coordination headaches before they start.

DC Structures: fast-track kits with price tags you can actually see

DC posts starting prices next to every model, so you can sort dreams from budgets before you call. The catalog skews contemporary, with glassy A-frame cabins, barn dominiums topped by black metal roofs, and lodge-style homes filled with clerestory light. Pick a template, tweak the floor plan, and a project coordinator walks you through upgrades such as SIP walls, Andersen windows, or factory-stained cedar siding.

Timeline

For most stock kits, DC quotes 10–15 weeks from signed drawings to outbound truck. The FAQ breaks it down to 8–10 weeks of design, 4–8 weeks of engineering, and 5–8 weeks of prefabrication, depending on complexity. Pre-cut, numbered parts let a local contractor, or an ambitious owner-builder with a crane day lined up, stand the frame in a long weekend and dry in the shell within a month.

Cost snapshot

The 3,134 ft² Thielsen model lists at $392,799, or roughly $125 / ft² for the material package. Smaller cabins start below six figures, while lodge-scale kits top half a million. DC estimates the kit covers about one-third of final turnkey cost, leaving room for foundation, mechanicals, and finishes.

Energy options

Standard pre-framed walls meet code in most climates, but many buyers choose SIPs (≈ R-24 walls, R-40+ roofs) for long-term efficiency without slowing the schedule.

Support and trade-offs

Every client gets a dedicated coordinator plus phone access to the engineering team, and DC keeps a referral list of builders familiar with its kits nationwide. You’ll work inside predefined engineering parameters, which helps speed and cost control but limits radical curves, and shipping from Oregon can nudge freight costs on the East Coast. Still, if you value upfront pricing, modern aesthetics, and a delivery date you can circle on the calendar, DC Structures offers a refreshingly straightforward path to a finished shell.

Side-by-side snapshot: costs, lead times, and DIY factor

The grid below distills written 2024–2025 quotes or price sheets from each vendor. Treat these as starting points; final numbers depend on plan size, finishes, and current lumber markets.

| Provider | Kit price (materials only) | What ships | Insulation baseline | Lead time | DIY factor |

| Hamill Creek | Frame ≈ $45 / ft²; lock-up shell ≈ $150 / ft² | Heavy-timber frame, hardware, drawings; shell adds SIPs, windows, doors | SIP walls R-24; roof R-50 | 12–16 wks | Moderate (crane day advised) |

| PrecisionCraft | Shell ≈ $100–$150 / ft² | Douglas-fir frame, SIP walls & roof, ICF foundation, raising crew | SIP walls ≥ R-26; roof R-40+ | 20–28 wks | Low (company crew handles frame) |

| Riverbend | Base package ≈ $120 / ft² | ICF foundation blocks, timber frame, pre-cut SIPs, on-site tech | SIP walls R-26; roof R-42 | 16–24 wks | Low (vendor erects frame) |

| DC Structures | Published per model; e.g., $125 / ft² for Thielsen | Pre-cut post-and-beam frame, wall/roof panels; window & siding options | Code-ready walls or SIP upgrade to R-24+/R-40 | 10–15 wks | Moderate-high (numbered parts, phone support) |

Prices cover the dry-in shell only. Budget separately for foundation, utilities, and interior finishes.

Two patterns emerge:

- Faster ships mean fewer custom moves. DC’s preset engineering turns drawings into a truckload in weeks; PrecisionCraft’s bespoke process takes months.

- DIY freedom shrinks as timber weight and pro crews increase. Hamill and smaller DC kits still welcome owner-builders, while PrecisionCraft and Riverbend trade sweat equity for factory crews and warranties.

Match the grid against your priorities—speed, energy savings, or single-contract convenience—and you’ll know which vendor to contact first.

Buyer FAQs: from permits to punch lists

Will the kit pass my local code review?

Yes. Each vendor ships engineer-stamped drawings calibrated to your snow load, wind zone, and seismic category. Most U.S. building departments accept them without redlines, as long as you submit soil and energy reports at the same time.

What has to be ready before the truck shows up?

- A dimension-checked concrete foundation with anchor bolts set to the shop drawings

- Temporary power and a gravel turnaround for a 53-foot trailer

- A crane or telehandler scheduled for frame raising (typically 6–8 hours for a 2,000 ft² kit)

Can I finance a kit home?

Nearly all banks treat it as a custom construction loan: 10–20 percent down, interest-only draws for land, kit payment, dry-in, and certificate of occupancy. Some lenders, such as U.S. Bank and Banner Bank, list prefab timber homes in their guidelines.

How much work can I DIY?

Plan to hire a crane crew for the timber frame, since raising day involves 4–6 workers and loads up to 2,500 lb. After dry-in, confident owner-builders often tackle interior framing, insulation top-ups, and trim to trim 10–15 percent off local labor costs.

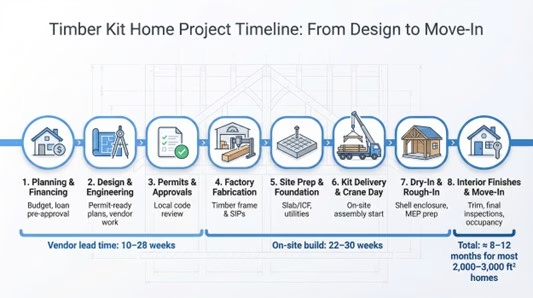

A typical timber frame kit project runs about 8–12 months from planning and engineering through delivery, dry-in, and move-in.

What’s a realistic order-to-move-in timeline?

Vendor lead time (10–28 weeks) plus on-site build (22–30 weeks) equals about 8–12 months for most 2,000–3,000 ft² projects, according to NAHB custom-home survey data. Weather, inspections, and change orders can add or subtract weeks.

Are these homes actually green?

Yes. A life-cycle study by FPInnovations found heavy-timber structures store 2.1 tons of CO₂ per 1,000 board ft. Pairing that with SIP walls that cut thermal bridging can lower annual heating loads by 40 percent compared with code-minimum stick framing.

What warranties apply?

Expect at least a 10-year structural warranty on the frame and manufacturer warranties on windows, roofing, and SIPs (often 20–30 years). Keep digital copies; some counties request them at final inspection.

Can I add on later?

Yes. Non-bearing partitions move easily, and designers can leave a “future gable” so a new wing ties into the existing bents. Budget an engineer’s review, usually $1,000–$2,000, to verify added loads and connection plates.

Conclusion

Armed with these facts, you can request quotes and meet lenders with data instead of guesswork.